Hardwood flooring is a well-liked product with trendy customers, and for good purpose. It’s clear, sturdy, and engaging. Whereas the ground’s look is partly decided by the kind of wooden you select, the best way the wooden is minimize can be an necessary issue. Not solely does it have a bearing on the looks of the product, however it additionally impacts how the wooden behaves after chopping.

Distinction Between Hardwoods and Softwoods

Once you’re contemplating wooden merchandise in your flooring, you’ll possible hear the phrases “hardwoods” and “softwoods” getting used. Each Hardwoods and Softwoods have distinctive seems and one over the opposite could fit your décor higher.

Hardwoods are deciduous bushes which have leaves, which they often lose within the fall once they go dormant. Any such tree produces both fruits or nuts. Most species of hardwoods can be utilized for manufacturing flooring, cabinetry and furnishings. Every kind of wooden has its personal grain patterns, some are open grain wooden reminiscent of Oak, Ash, Chestnut, Hickory or Elm. Others are open closed grain reminiscent of Cherry, Maple, Birch and Walnut. Select both open or closed grain there shall be coloration, texture and markings, which provide you with loads of selection when making a call about flooring in your dwelling or workplace.

Softwoods are bushes with needles as an alternative of leaves. Examples of softwoods are

- Cedar

- Fir

- Hemlock

- Pine

- Redwood

- Spruce

Totally different Sorts of Wooden Flooring Cuts

Regardless that all hardwood flooring are created from actual wooden, the properties of every kind differ in methods apart from the bushes’ hardness. The area the place the bushes grew, the tactic used to noticed the log for flooring and the style wherein it’s dried mix to create a novel ground.

Artisans prize bushes harvested from northern forests for his or her constant coloration and tighter progress rings as a result of slower rising season. Additionally they produce a extra fascinating finish product. The kind of flooring minimize made into the wooden on the sawmill makes a distinction within the look and high quality of the flooring.

The various kinds of flooring cuts are as follows:

Plain Sawn

That is the most typical kind of flooring minimize used at present. Also referred to as flat sawn, it entails staff chopping a aspect of the log after which turning it 90 levels earlier than the following minimize is made. The method continues in the identical trend till they use the whole log. Regardless that it’s an environment friendly technique of chopping wooden, it produces extra waste materials than stay sawn milling.

Graining in plain sawn wooden is between 0-30 levels. Consequently, you’ll see giant, open patterns on the boards. These are known as a “cathedral impact,” since they resemble the steeples of those giant locations of worship.

Many homes constructed within the early-to-mid 1900s had each quarter sawn and plain sawn pink and white oak flooring. The floorboards measured 1-1/2”, 2-1/4” and three inches throughout and for numerous folks, that is what “conventional” oak flooring seems like.

Rift Sawn

Step one in rift sawing wooden is to chop it into quarters. Subsequent, the wooden is minimize radially perpendicular to its progress rings. Any such minimize produces grains at angles of 30-60 levels, with 45 levels being probably the most fascinating.

It’s the costliest approach to noticed wooden, and certain because of this, it’s used the least usually. The results of the cuts is a straight grain sample with discernible flecking. Any such minimize has the potential to supply flooring boards of beautiful magnificence and excessive stability with a linear look that you simply don’t get with different forms of cuts. When you’ve got your coronary heart set on having hardwood in your house with a protracted, straight grain sample, you’ll wish to search for boards which have been rift sawn. With one of these minimize, it’s very tough to get floorboards wider than 4 inches and higher throughout. Any such minimize in softwood flooring could be referred to as Vertical Grain.

Quarter Sawn

When a log is being minimize for quartered flooring, because the title implies, step one is the minimize it into quarters. Subsequent, it’s minimize perpendicular to the expansion rings within the log. It produces tight graining at angles of 60-90 levels, leading to which can be near the floor of the boards. The ensuing sample is gorgeous flecks of coloration from the wooden’s medullary rays (ribbons that reach vertically by means of the tree, perpendicular to the expansion rings).

Quarter sawn milling is costlier than plain sawn, and this technique produces extra waste materials. Boards sawn utilizing this technique are usually narrower than ones minimize utilizing the plain sawn technique. Purple and white oak is mostly quarter sawn in an effort to exhibit the wooden’s distinctive straight, striped grain.

This technique of sawing wooden for flooring matches the wooden grain of Mission-style furnishings. If you wish to create a coordinated look together with your flooring and furnishings, you’ll wish to preserve this element in thoughts.

Dwell Sawn

With this technique, the log is minimize straight by means of with every move. Subsequent cuts are parallel to the primary one. The yield is a mixture of plain, rift and quarter sawn woods; there shall be about one-third of every per log. Since all of the cuts are straight, this technique is just about waste-free. This technique additionally produces the favored wider boards widespread with customers.

Moisture Content material in Wooden

Wooden is a fabric that expands and contracts with adjustments in moisture within the environment. This property means boards minimize for flooring will swell and shrink in sure methods relying on the particular technique used. Because of the course of the expansion rings, plain sawn boards change in dimension in width. The broader the board is to start with, the higher the potential for change. Rift sawn and quarter sawn boards will develop and contract in thickness because of adjustments in moisture.

How Hardwood is Dried

Drying the lumber used for a hardwood ground is without doubt one of the most necessary features to how the completed product seems in a house. On the floor, this seems to be a really mundane job. It’s not possible to inform from taking a look at a board whether or not it was dried utilizing the correct strategies or not. Nevertheless, if you wish to have a secure and high-quality wooden ground, it’s crucial to begin with supplies that have been dried correctly.

Earlier than you may perceive the procedures concerned in drying wooden, it’s necessary so that you can perceive the best way a tree grows. Their medullary rays act in the identical manner because the veins in your physique — they transport vitamins by means of the trunk to the components of the tree the place they’re wanted whereas the tree is within the floor.

When a log is minimize into lumber, the medullary rays are clearly seen. In species of bushes like white oak, they’re particularly pronounced. The medullary rays run perpendicular to the annual progress rings that the bushes create annually. When a tree is standing, it creates a progress ring across the trunk, operating parallel to the bottom — the medullary rays run vertically from roots to leaves.

After chopping, the lumber releases moisture by means of the medullary rays. For that reason, plain sawn and quarter sawn wooden doesn’t dry in the identical method. In a plain piece of wooden, the medullary rays run perpendicular to the floor, which signifies that moisture has to maneuver out of the board by means of the thickest half.

In a 4/4-inch piece of lumber, moisture from the middle has to maneuver roughly one-half inch from the center to make it out of the board. The lumber will dry extra rapidly than 1 / 4 sawn piece of lumber, since moisture in a 4/4 by 6-inch quarter sawn board must transfer three inches from the middle in an effort to escape. For the reason that moisture must transfer additional in an effort to evaporate, it could take longer to dry.

Kiln Drying Lumber

The kiln used to dry lumber is a well-insulated room the place the next parts may be managed and maintained:

- Temperature

- Relative Humidity

- Air Circulation

Compartment and Progressive Kilns

There are two basic forms of kilns, compartment or progressive. Compartment kilns may be loaded with lumber unexpectedly. Your entire load of lumber stays stationary in the course of the drying course of. The operator can alter temperature and humidity because the wooden dries.

A progressive kiln can accommodate a load consisting of wooden at varied phases of drying on the similar time. Two thermometers are used to watch the drying circumstances alongside the size of the kiln.

Time Required to Dry Lumber

The precise time it takes to dry a specific kind of lumber varies, relying on thickness, the preliminary moisture content material and the character of the wooden. The kind of kiln additionally has a bearing on the time it takes to dry a load of lumber, as properly.

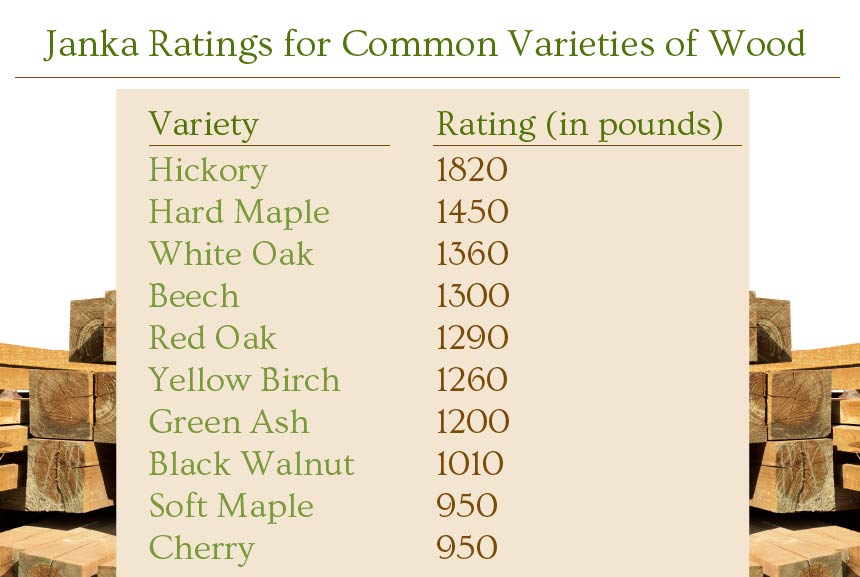

Janka Wooden Hardness Scale

The Janka Ratings System ranks the relative hardness of various kinds of wooden. Once you’re contemplating particular forms of wooden for flooring, needless to say softer woods will present put on and tear extra rapidly than more durable forms of wooden. In the event you’re searching for a kind of wooden for a high traffic space in your house or workplace, you’d be higher off with a range with a better score. The upper the quantity, the more durable the wooden and the much less possible it’s to indicate put on and tear from common use if clean.

What’s Reclaimed Strong Hardwood Flooring?

Reclaimed strong hardwood flooring makes use of wooden that was collected from barns and different agricultural outbuildings. This wooden might be wherever from 75 to 200 years outdated. For the reason that unique builders of the buildings tended to make use of domestically accessible bushes for constructing functions, greater than possible the lumber is from forests that existed previous to the world being settled. The grain of the wooden was tighter than what is obtainable at present because of slower progress skilled.

Selecting a Reclaimed Wooden Flooring Firm

Once you’re selecting a reclaimed wooden flooring firm, you’ll wish to you’ll want to do your due diligence. You should be sure that you’re coping with an organization that’s respected and staffed with staff who’ve been within the enterprise lengthy sufficient that they know methods to choose the fitting wooden for the challenge you take into account.

- Inquire in regards to the supply of the lumber used to make the flooring to make sure it’s from barns and different farm buildings initially constructed from outdated progress bushes and to make sure that new or “pallet” wooden isn’t being combined in.

- Previous progress bushes are extra fascinating, since they’re stronger and extra immune to rot. Attributable to their low moisture content material, outdated progress bushes are much less prone to be dwelling to bugs who would in any other case feed on the wooden.

- You’ll want to ask for pictures of the flooring firm’s earlier work, in addition to samples of various kinds of reclaimed wooden flooring which can be accessible.

- The gross sales consultant must be educated in regards to the merchandise and capable of reply your questions, or keen to search out out solutions for you.

- Take a look at a number of samples to find out whether or not the flooring has tongue and groove and does the tongue and groove match collectively on a flat floor.

- Ask the producer whether or not the corporate offers particulars to its prospects about manufacturing and transport as a basic coverage.

- All the time ask what’s your waste issue when ordering a reclaimed ground.

Inquire about precautions that they’ll take to guard the flooring whereas in transit to your location.

There are nonetheless locations all over the world the place you will discover outdated progress lumber, however it could be a really costly proposition to entry it. In North America, keen manufactures principally depleted the provision of outdated progress lumber by the center of the final century. The American Chestnut, together with another species, have been very practically worn out.

Reclaimed wooden is an environmentally pleasant supply of flooring supplies, because you’re reusing present assets to beautify your house as an alternative of consuming extra merchandise. In return, you’re getting a extremely useful, stunning hardwood ground with the potential to final for a lot of a long time. As talked about, the wooden used to trend barns and different agricultural buildings is superior to what’s accessible for harvest at present.

All you should do now’s choose the particular kind of flooring milled from outdated progress lumber that appeals to you most. We invite you to view our Heirloom Sequence of huge plank flooring. Out there in lengths starting from 2-12 ft, there are a variety of tones to swimsuit any style and adorning plan. Contact us at present to find extra about our hardwood flooring and different merchandise.